What is the role of 3D printing in orthopedics? 3D printing offers new sophisticated solutions for manufacturing next-generation orthopedic implants.

‘3D-printed metal implants could last longer than regular implants, be more durable and potentially save the medical industry money.’

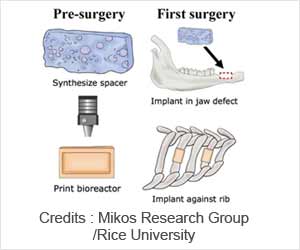

3D printing offers a fast process for the manufacture of custom-made implants. Its manufacturing precision and almost free geometric control provide a completely new paradigm for the development of implants.By exploiting the good features of the manufacturing process, it can address the shortcomings of traditional implants in terms of both mechanical properties and biocompatibility. 3D printing enables the development of complex structures that other manufacturing methods cannot achieve.

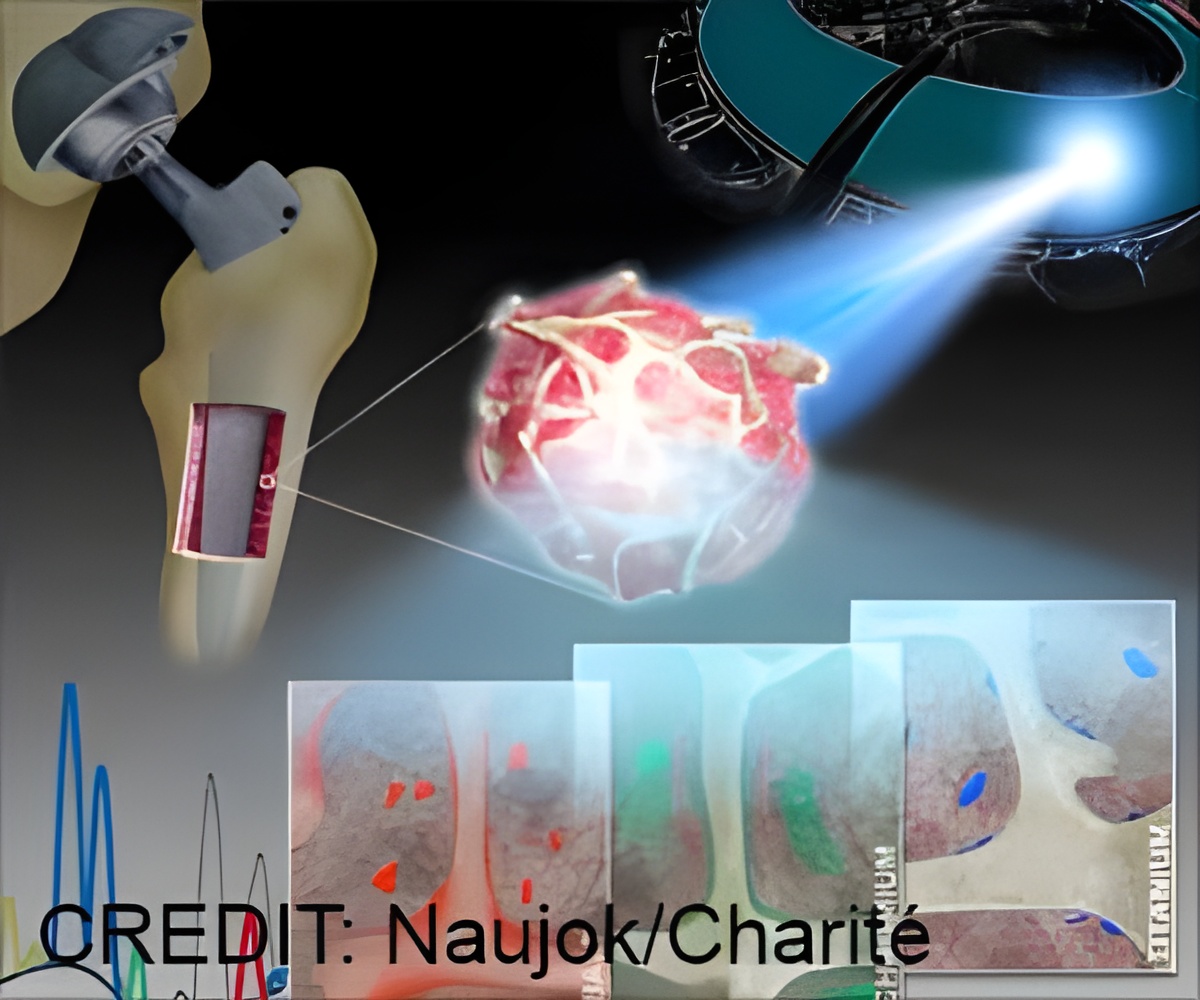

In orthopedic applications, the main technical challenge is the high stiffness of the metals concerning the different bone types. In use, a conventional rigid metal implant localizes the deformation on the surrounding bone tissue and can lead to premature failure.

3D Printing in Orthopaedic Surgery: Current Applications and Future Developments

A new study has shown that by 3D printing purpose-designed pore structures instead of solid structures, the structural stiffness of implants can be optimized to meet the stiffness of different bone types. In addition, porosity can be controlled so that the implant surface can be made partially solid for durability but partially porous to enhance osseointegration and tailor the stiffness.The new type of implant takes advantage of these features so that it can be attached to the bone without screws. In this case, the bone tissue grows into the implant within the porous areas. The highly porous inner structure of the implant provides an excellent platform for the growth of blood vessels and nerve tissue.

The developed architectured materials can significantly reduce stress damage at the bone-implant interface and prolong the life of the implant. The structures developed can be used in the most common orthopedic applications, such as the hip, knee, or spine, but also in less common sites.

Advertisement

3D printing allows for the shortening of the production chain as the rough and porous surface, often essential for biocompatibility, no longer needs to be produced separately by subsequent surface treatments.

Source-Medindia