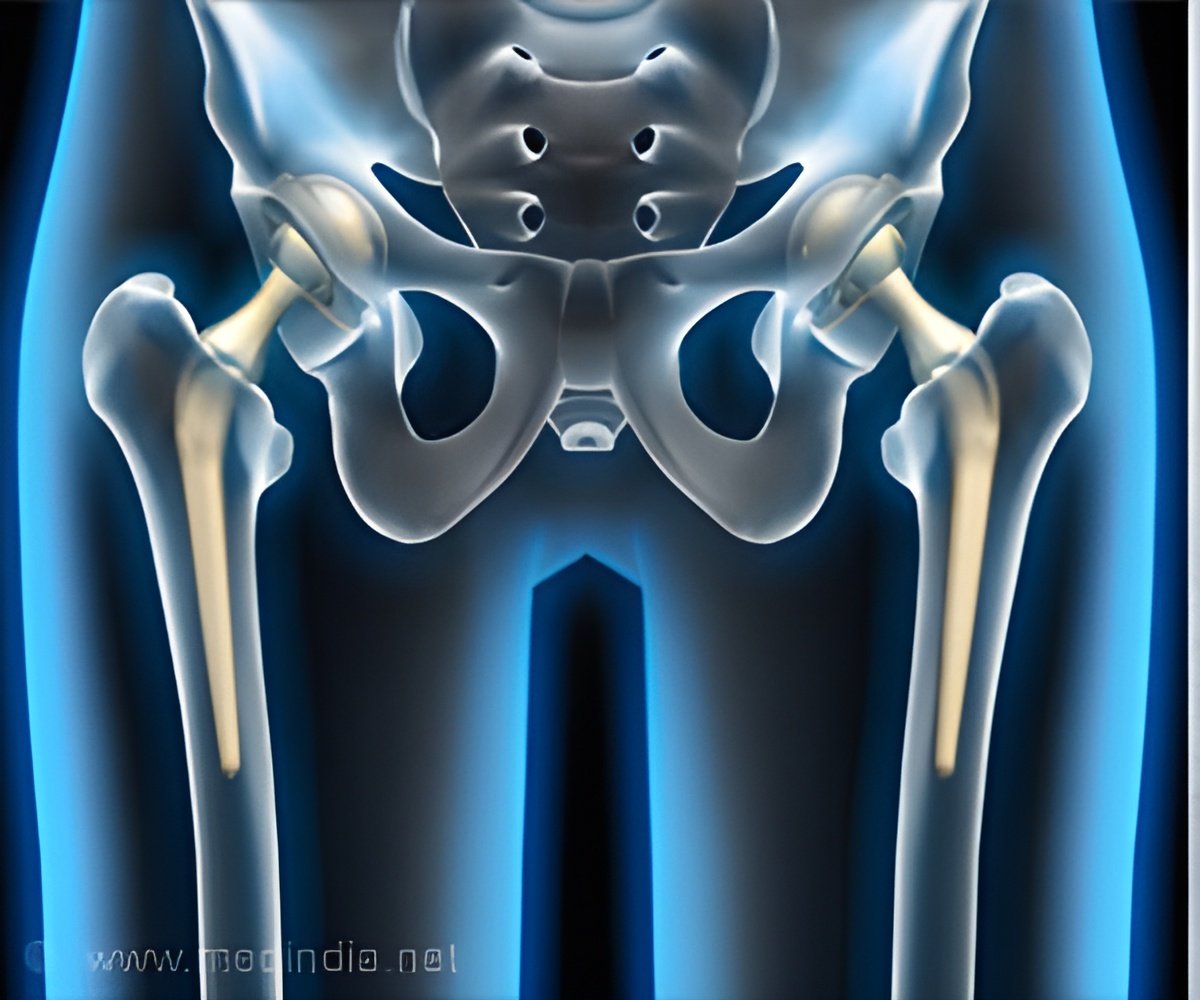

Artificial implants can be improved by incorporating principles like fluid dynamics, contact dynamics and fluid mechanic thereby improving the patients’ quality of life.

‘Artificial implants can be improved by incorporating principles like fluid dynamics, contact dynamics and fluid mechanic thereby improving the patients’ quality of life.’

Read More..

The Brown School of Engineering lab of mechanical engineer Fred Higgs conducted a computational study that simulates and tracks how hips evolve, uniquely incorporating fluid dynamics and roughness of the joint surfaces. They also included factors clinicians typically use to predict how well implants will stand up over their expected 15-year lifetime.Read More..

The immediate goal of the team was to advance the design of more robust prostheses. The researchers stated that the model can help clinicians personalize hip joints for patients depending on gender, weight, age, and gait variations.

The researchers felt the need to look beyond the limitations of previous mechanical studies and standard clinical practices that use simple walking as a baseline to evaluate artificial hips without incorporating higher-impact activities.

Christian said, “When we talk to surgeons, they tell us a lot of their decisions are based on their wealth of experience. But some have expressed a desire for better diagnostic tools to predict how long an implant is going to last. Fifteen years sounds like a long time but if you need to put an artificial hip into someone who's young and active, you want it to last longer so they don't have multiple surgeries.”

The researchers wanted to know how long their best candidate hip joints would last. The model uses walking motion of real patients.

Advertisement

The new study incorporates four distinct modes of physics- fluid dynamics, contact mechanics, particle dynamics, and wear which play an important part in hip motion. According to the researchers, no previous studies considered all four simultaneously.

Advertisement

Higgs said, “In healthy natural joints, the fluid generates enough pressure so that you don't have contact, so we all walk without pain. But an artificial hip joint generally undergoes partial contact, which increasingly wears and deteriorates your implanted joint over time. We call this kind of rubbing mixed lubrication."

This rubbing can increase the generation of wear debris, especially from the plastic material - an ultrahigh molecular weight polyethylene commonly used as the socket (the acetabular cup) in artificial joints. These particles of size 5 microns mix with the synovial fluid can sometimes escape the joint.

They can eventually loosen the implant or can cause the surrounding tissue to break down and often get carried to other parts of the body, where they can cause osteolysis.

The researchers noted that the metal sockets are more durable. However, if the metal shavings break off and accumulate, they can cause much more damaging effects than polyethylene particles.

The researchers noted future models will incorporate more novel materials being used in joint replacement.

Source-Medindia