How would you like to get a kidney in no time rather than wait for a donor? 3D printing technology may be able to do just that in the near future.

What is 3-D Printing?

3-D printing is a process of making three dimensional solid object from any digital object by using additive processing technology which involves creating and laying down successive layers of the material using a computer aided design (CAD) package or a 3D scanner.

Various additive processes are used in 3-D printing. Some of them are as follows:

• Melting or softening material to produce sequential layering

• Curing liquid material

• Laminated object manufacturing where thin layers are cut to shape and joined together

These technologies use common materials such as metal alloys, for example, titanium alloys, stainless steel or materials like metal powders, ceramic powder, plaster, and even plastic films.

3-D bio-printing and Tissue Engineering

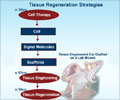

They also want to take a step further to create fully functional tissue replacements and print it using 3-D bioprinters so that surgeons can use them to repair or replace damaged tissues and organs by a process called tissue engineering.

Surgeon Anthony Atala and his colleagues at Wake Forest Institute for Regenerative Medicine are working on regenerating and growing tissues and organs and currently they are developing a technology that can ‘print’ human tissue on demand. To make the tissue ‘prints’ functional, these tissues need a network of blood vessels to make them living, and of course making 3D prints of blood vessels is not an easy thing to do because the vascular system has to be provided with life sustaining oxygen and nutrients and also a way to remove carbon dioxide and waste material.

Bio-engineers have developed many ‘bioprinters’ and the most often used one is the ‘inkjet inspired’ printer in which cells are used like ink. Substances like hydrogel or collagen are used to hold the cells together. Harvard researchers have developed a kind of ‘ink’, one that melts as it cools. They first printed a network of interconnected filaments, then melted the material by chilling them and then suctioned the liquid out thus creating a network of vessels (tubes).

“Tissue engineers have been waiting for a method like this,” said Don Ingber, Judah Folkman Professor of Vascular Biology and Professor of Bioengineering at Harvard and founding director of the Wyss Institute.

He believed that the ability to form functional 3D blood vessel networks before they are implanted will cause thicker tissues to be formed, and also greatly increase the chances of their engraftment and survival."

Reproducing cells through cell culture has been resorted to by scientists for years, but 3D printing gives the advantage of reducing the costs and offers an opportunity of printing an entire organ rather than just pieces.

Source-Medindia