The research team has developed a new device known as Bio-Pick, Place, and Perfuse (BioP3), which lifts different components and stacks them into larger groupings

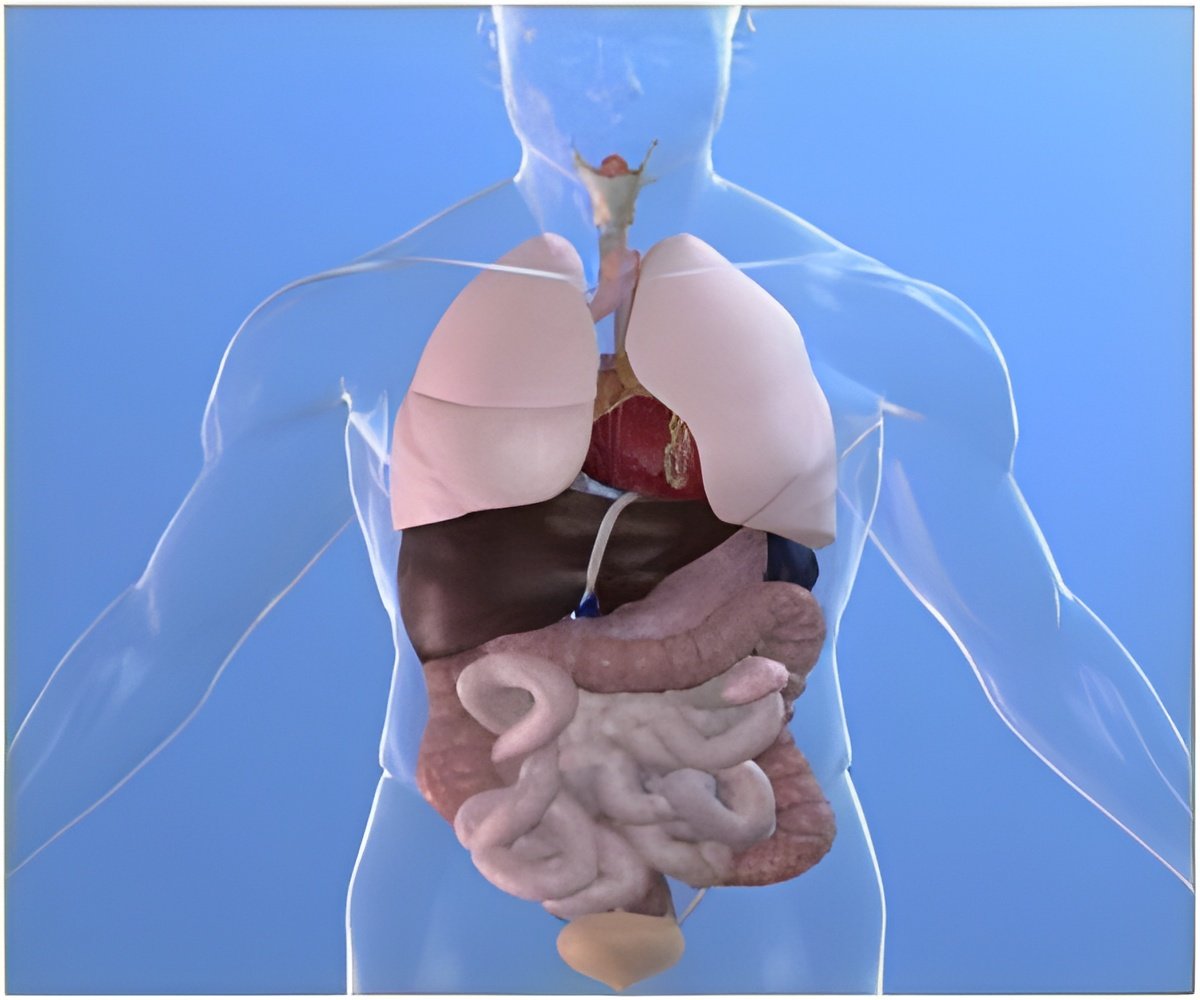

A variety of diseases can be treated with engineered biological tissues when used as replacement organs, even though the main challenge faced today is to scale and combine groups of cells into larger structured. Even though 3-D printing is a promising new technology, the building of a complex group using different kinds of cells may be inappropriate for this technology. Researchers at the Brown University have taken a different approach that takes inspiration from the microelectronics industry to build tissue constructs from different complex parts.

The research team has developed a new device known as Bio-Pick, Place, and Perfuse (BioP3), which lifts different components and stacks them into larger groupings, similar to how circuit boards are assembled. The tissues actually blend with each other, forming systems that are functional and can be created in different shapes without relying on scaffolds.

A study on the BioP3 says that:

"As many as sixteen toroids were stacked over a 170 micron diameter post where they fused over the course of 48 hours to form a single tissue. Larger honeycomb parts were also gripped and stacked onto a build head, which, like the gripper head, provided fluid suction to hold as well as perfuse the parts during assembly. Scaffold-free building parts help to address several of the engineering and biological challenges to large tissuebiofabrication, and the Bio-P3 described in this paper is a novel instrument for the controlled gripping, placing, stacking, and perfusing of living building parts for solid organ fabrication.”

Source-Medindia