SMART researchers develop a new fast, efficient and cost-effective method that can produce Red Blood Cells with high purity and full functionality.

‘Researchers modify existing Dean Flow Fractionation (DFF) and Deterministic Lateral Displacement (DLD) technologies to develop a faster, more efficient and cost-effective method to develop RBCs. Purified RBCs are fully functional and have high purity.’

Read More..

The novel method of RBC production cuts the culture time by half when compared to existing methods. It also uses novel sorting and purification methods that are more precise, faster and less costly.Read More..

Blood transfusions save millions of lives, but many countries do not have sufficient blood supply. Producing RBCs on demand, especially O+ blood which is the universal donor would be significantly beneficial.

Faster and simpler manufacturing of RBCs would also have a significant impact on blood banks worldwide and reduce dependence on donor blood which has a higher risk of infection. However, manufacturing RBCs is time-consuming, not optimal, costly and creates undesirable by-products.

The researchers have designed an optimized intermediate cryogenic procedure. The storage protocol reduces the cell culture time to 11 days post-thaw. It eliminates the need for continuous 23-day blood manufacturing.

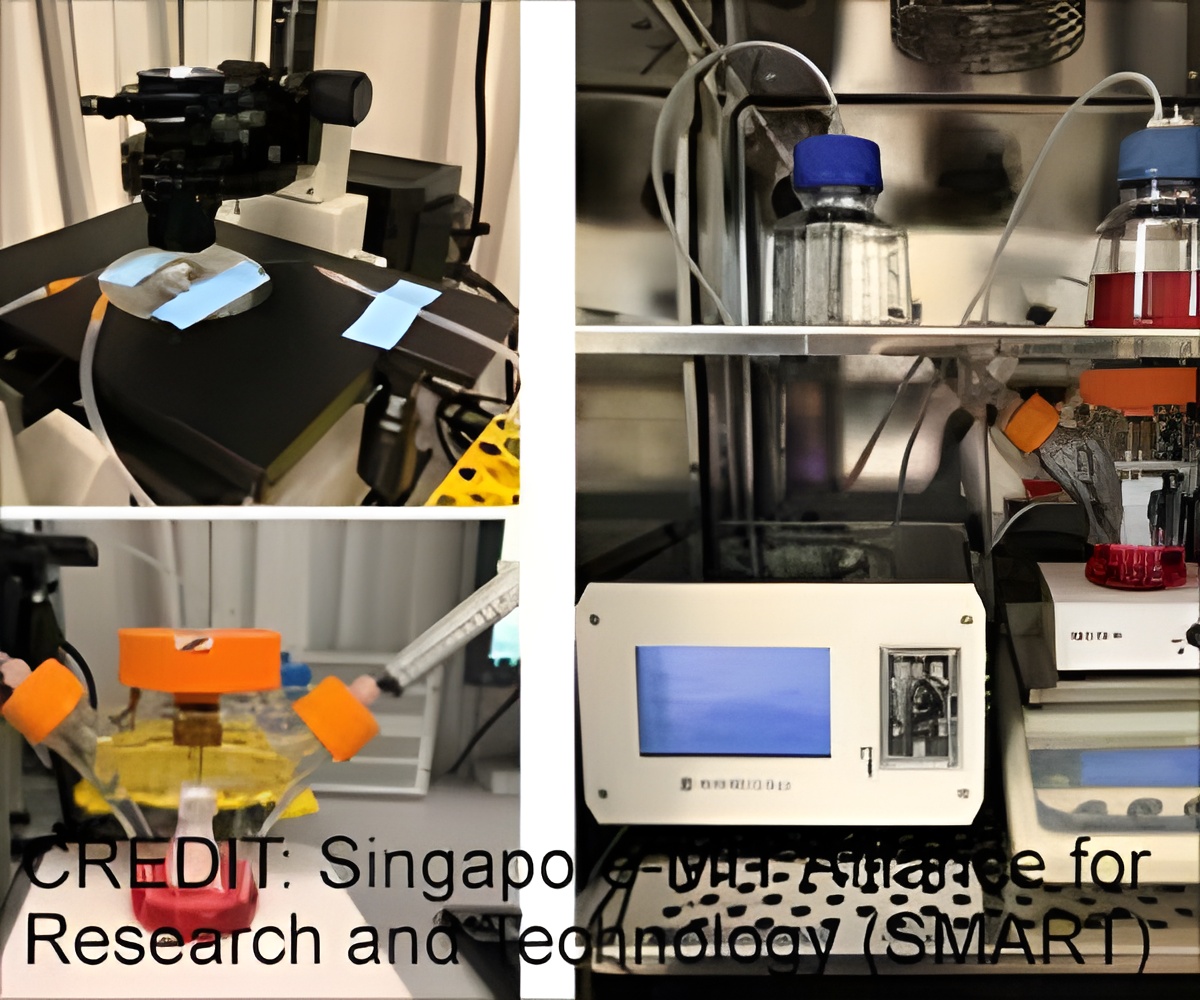

The protocol is aided by complementary technologies the team developed for highly efficient, low-cost RBC purification and more targeted sorting.

Advertisement

The researchers developed a trapezoidal cross-section design and microfluidic chip for DFF sorting, and a unique sorting system was achieved with an inverse L-shape pillar structure for DLD sorting.

Advertisement

The purified RBCs were found to retain their functionality as demonstrated by high malaria parasite infectivity.

High malaria parasite infectivity requires very pure and healthy cells for infection. This further confirms that the new RBS sorting and purifying technologies can also be used for investigating malaria pathology.

The purified RBCs, when compared to conventional cell purification, offer comparable purity while processing at least twice as many cells per second at less than a third of the cost.

DFF is more optimal in the scale-up manufacturing process for its high volumetric throughput.

DLD’s high precision feature is highly advantageous for pure RBC’s.

These processes do not require a trained technician to perform sample handling procedures and are scalable for industrial production.

The technologies would provide scientists with faster access to fully functional and highly pure cell products.

Source-Medindia