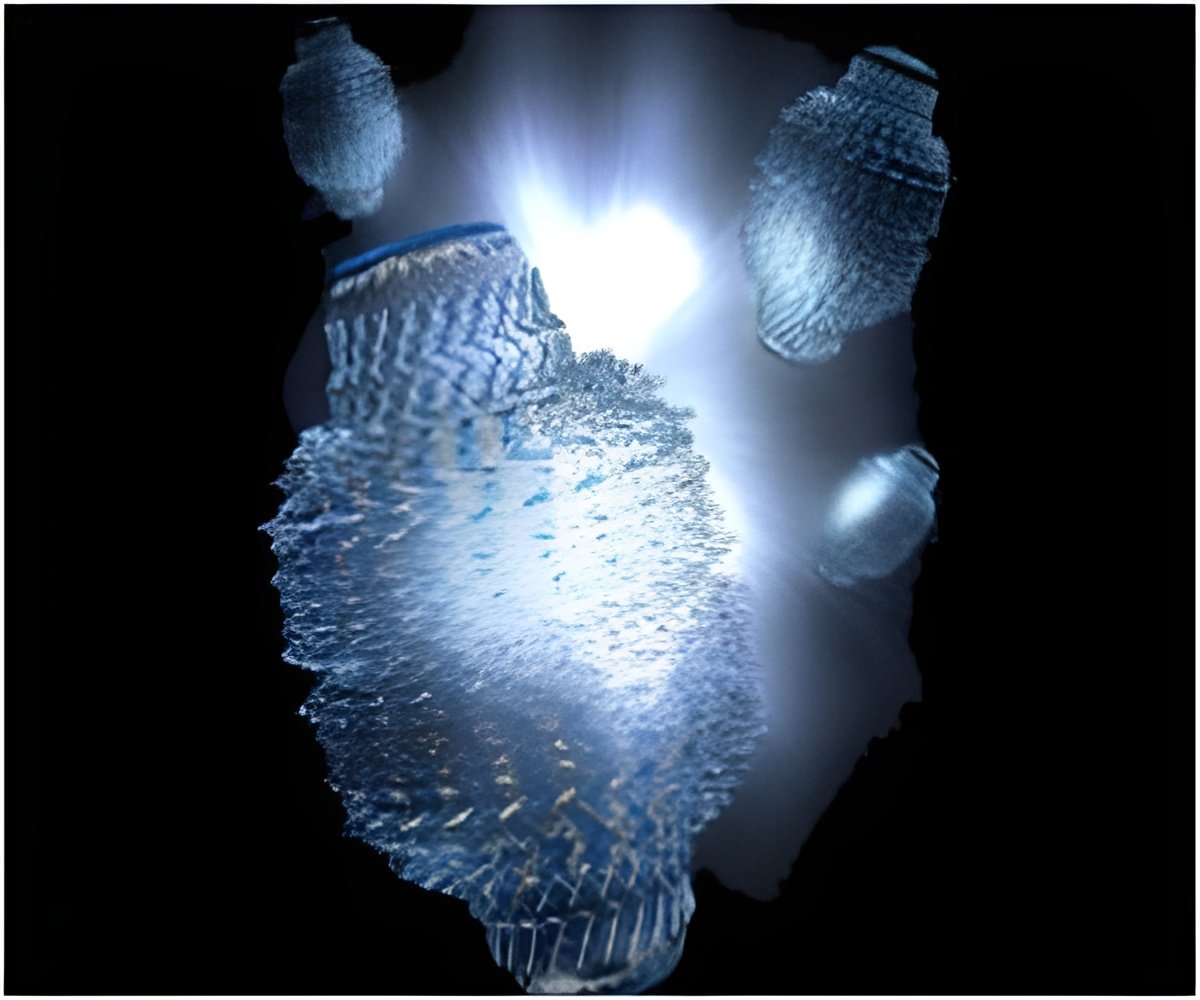

Researchers at University of Utah have managed to produce a nanocrystal semiconductor.

Using microwaves "is a fast way to make these particles that have a broad range of applications," says Michael Free, a professor of metallurgical engineering. "We hope in the next five years there will be some commercial products from this, and we are continuing to pursue applications and improvements. It's a good market, but we don't know exactly where the market will go."

Free and the study's lead author, Prashant Sarswat, a research associate in metallurgical engineering, are publishing their study of the microwaved photovoltaic semiconductor – known as CZTS for copper, zinc, tin and sulfur – in the June 1 issue of the Journal of Crystal Growth.

In the study, they determined the optimum time required to produce the most uniform crystals of the CZTS semiconductor – 18 minutes in the microwave oven – and confirmed the material indeed was CZTS by using a variety of tests, such as X-ray crystallography, electron microscopy, atomic force microscopy and ultraviolet spectroscopy. They also built a small photovoltaic solar cell to confirm that the material works and demonstrate that smaller nanocrystals display "quantum confinement," a property that makes them versatile for different uses.

"It's not an easy material to make," Sarswat says. "There are a lot of unwanted compounds that can form if it is not made properly."

Sarswat says that compared with photovoltaic semiconductors that use highly toxic cadmium and arsenic, ingredients for CZTS photovoltaic material "are more environmentally friendly."

Advertisement

Advertisement