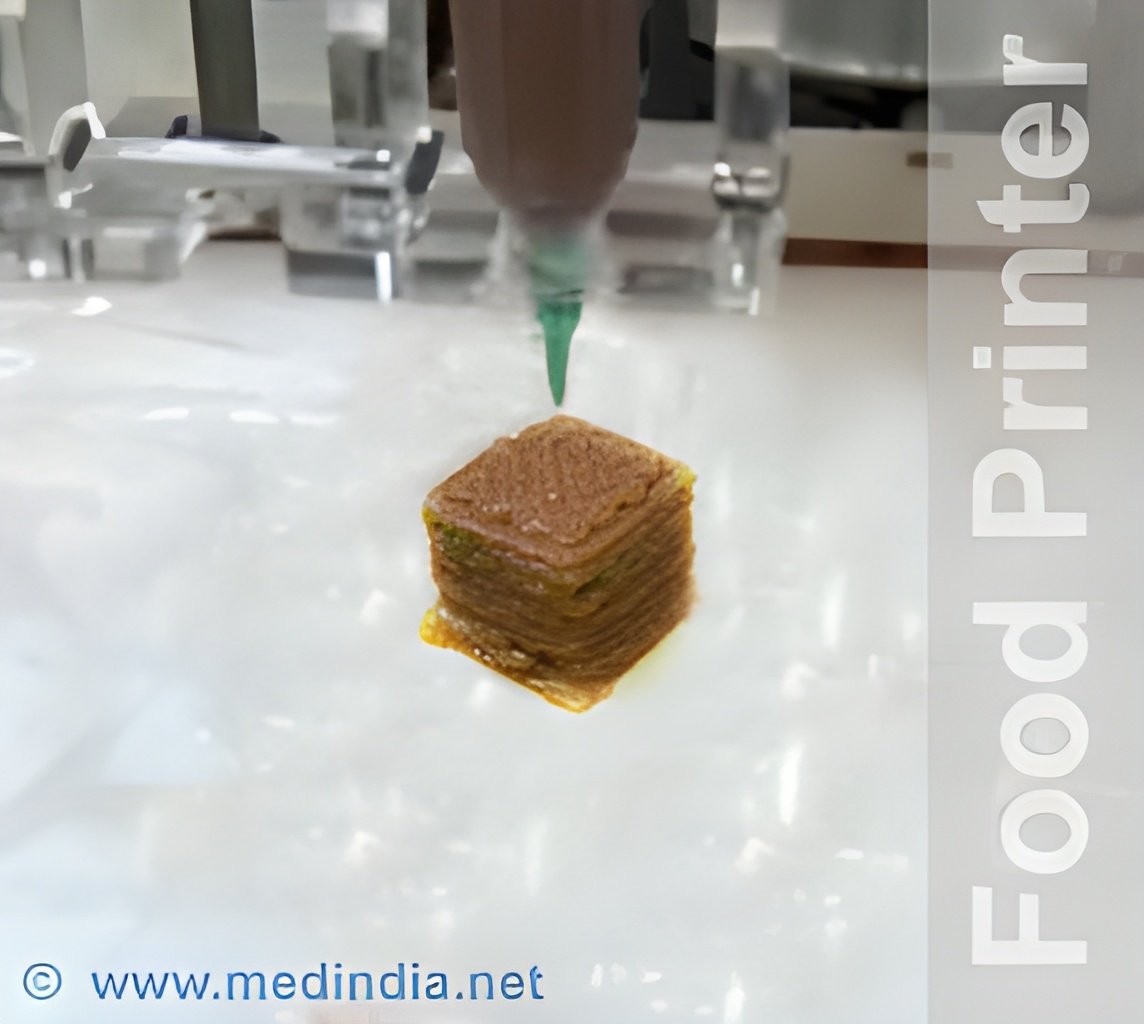

Singapore researchers develop a new method for printing food for patients with swallowing difficulties.

Pureed //foods in liquid or semi-solid form are used to make food inks. The food is assembled layer by layer after being 3D-printed by extrusion from a nozzle.

Patients with swallowing difficulties (dysphagia) are usually served pureed foods. Healthcare professionals normally use silicone molds to shape pureed foods to present them in a more visually appealing and appetizing way. This method is not only labor and time-intensive but requires storage. 3D printed food can be easily produced with the desired shape and texture in a shorter time.

Prof Yi Zhang, lead researcher, said, "Our technology helps to provide dysphagic patients with adequate nutrient-rich and safe diets. Their feeding is more dignified, enabling them to socialize and consume meals that look, feel and taste like regular food. Our method of 3D printing fresh vegetables can be used easily in hospitals, nursing homes, daycare centers for the aging population with dysphagia and other swallowing disorders. Our research is also another step forward in digital gastronomy, where we can cater to specific requirements prescribed by dieticians, such as nutrition customization and visual appeal."

However, food inks made from dehydrated food and freeze-dried powders usually contain many food additives like hydrocolloids (HCs) to stabilize the ink and make the printing process smoother. But the addition of HCs in high quantities changes the taste, texture, and aroma of the printed food, making it unpalatable, leading to reduced food consumption and malnutrition among patients.

The Singapore research team overcame this challenge by using fresh and frozen vegetables to make the food inks stable. They were able to preserve the nutrition of the printed food better as well as make it more appetizing, which should solve the issue of malnutrition.

The team also found that not all vegetables required hydrocolloid treatment and could be broadly classified into three categories requiring different hydrocolloid treatment levels to be printable. For example, garden pea requires no HCs, carrot requires one type of HC, and bok choy requires two types of HCs.

Gladys Wong, co-lead researcher, said, "3D Food Printing is more than a novelty. I believe it will be a viable approach in the near future in providing sustenance and nourishment to our increasingly aging population. Our frail, elderly patients, as well as those with swallowing difficulties, will be able to enjoy a visually presentable and pleasurable dining experience even with a restrictive diet of smoothly pureed dishes."

Source-Medindia